A multiphase flow is the simultaneous flow of materials with different states or phases (i.e. gas, liquid, or solid). Particularly, two-phase flows consisting of solid particles within a liquid are ubiquitous in many engineering fields, such as mining, chemical, and oil and gas. The FLUIDLab group has been dealing with multiphase flows for some years, and two main topics have been the focus of research.

Impact erosion

The impact erosion is the removal of material from a surface subjected to the impingements of solid particles dragged by a fluid. The research of the FLUIDLab group is aimed at the characterization and the numerical prediction of the impact erosion, and it is organized in different sub-topics.

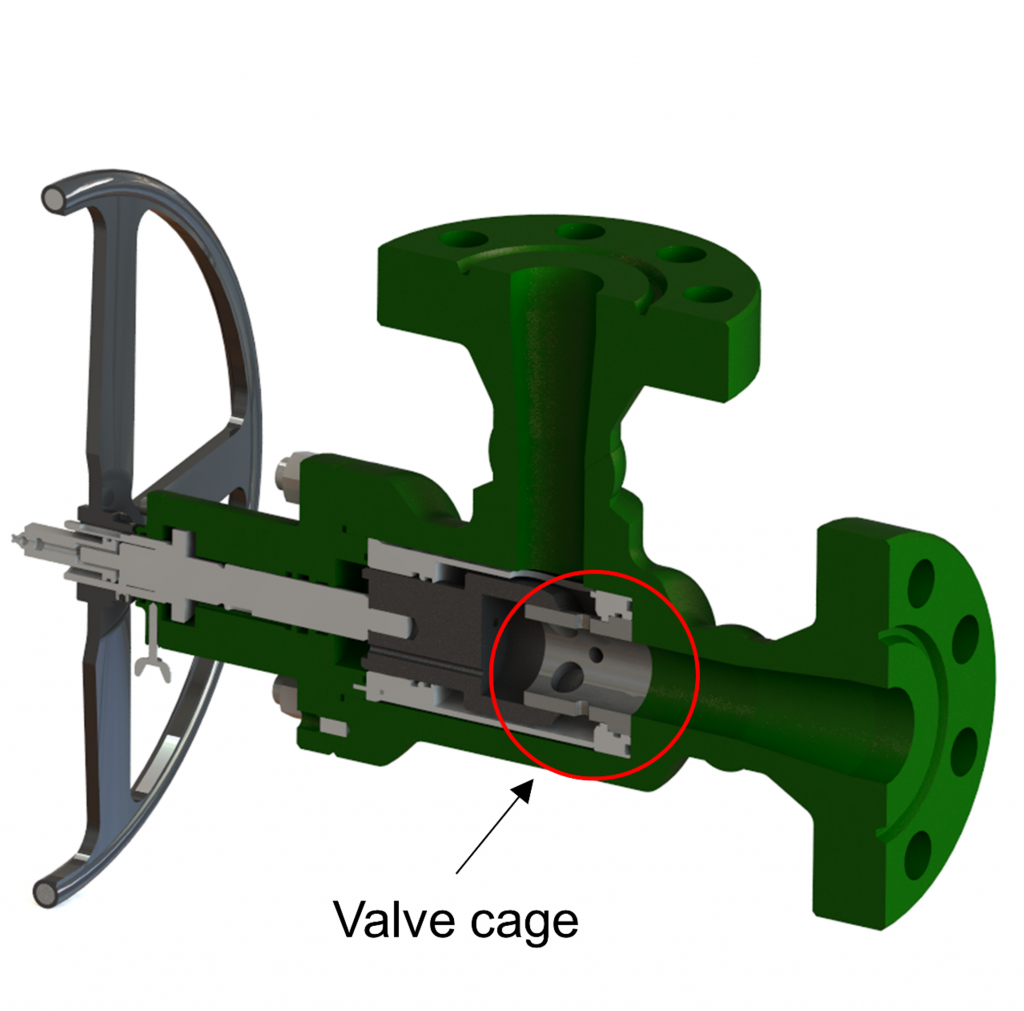

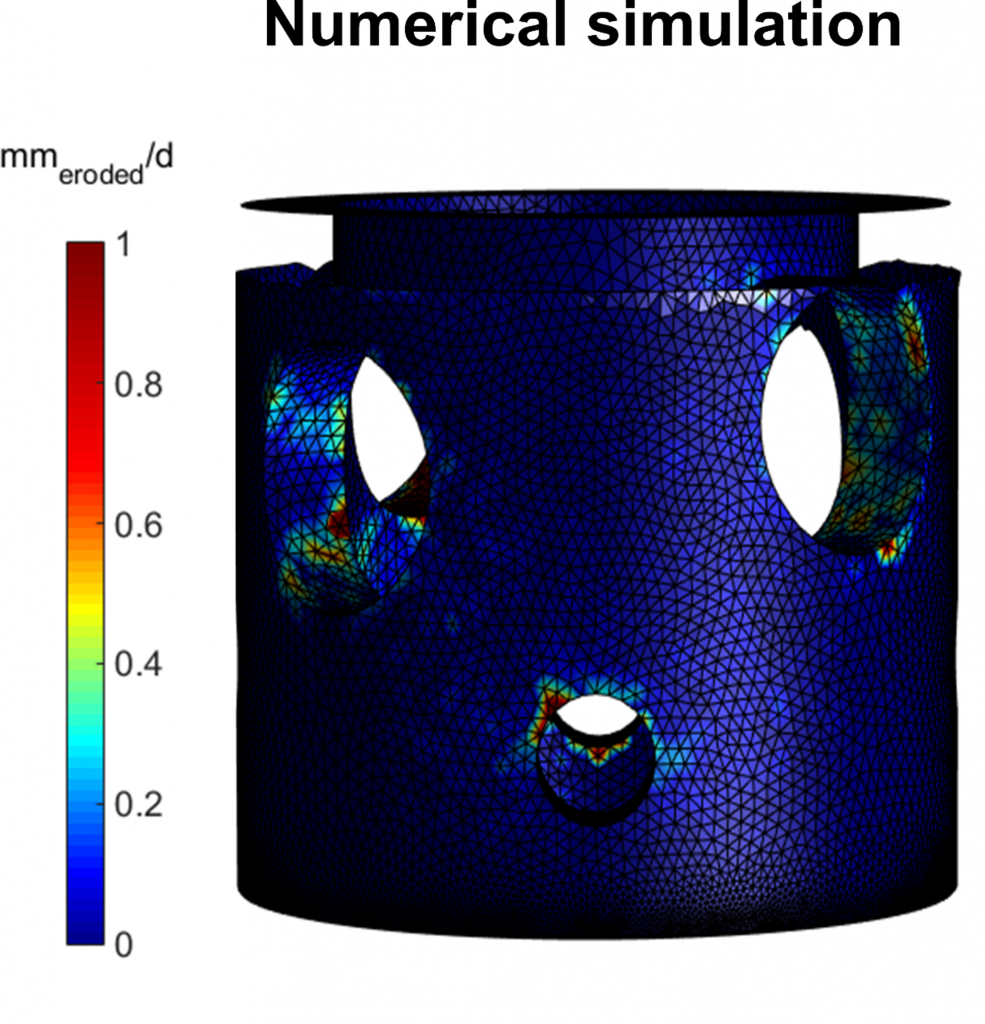

The main one, based on the E.P.I.C.O. (Erosion Prediction in Control Operation) research contract between Politecnico di Milano and ENI S.p.A., is the development of methods for estimating the useful life of valves in fields with sand production. To this aim, research is being carried out to improve the capacity of predicting the impact erosion through innovative computational methods. In addition to the numerical activities, experimental testing on two specifically designed rigs allows better understanding of the impact erosion mechanisms and it provides data to validate the developed models. The goal of the project has been achieved through a multi-stage process involving Computational Fluid Dynamics and experimental testing. Firstly, the characterization of the erosion behaviour of the materials of the valves was provided through slurry jet impingement tests. The outcomes of numerical simulations, performed following the standard, well-established approach involving Eulerian-Lagrangian modelling of the liquid-particle flow and application of an algebraic erosion model, were compared against the laboratory data. This allowed proper definition of the erosion prediction models and assessment of their reliability for the flow conditions of interest. Secondly, the developed models were validated by the reproduction of the erosion tests on the actual devices performed in a dedicated slurry flow loop. The models proved capable in estimating the location of the erosion hotspots and the erosion rate of the most vulnerable valve components. Thirdly, a number of virtual experiments of valve erosion were numerically performed for different operating conditions (that is, valve opening, type of abrasives, and fluid dynamic conditions). Fourthly, models for useful life-time predictions have been developed based on the collected results. This approach has been applied to two different devices, namely a cage and sleeve choke valve and a gate valve. The good results obtained so far opens promising perspectives for the continuation of this research. Other erosion-related activities concern the investigation the solid impact erosion of concrete, with application to hydraulic structures, the prediction of silt erosion in Pelton turbine components, and the experimental characterization of the erosion of GRE materials.

Slurry Flows

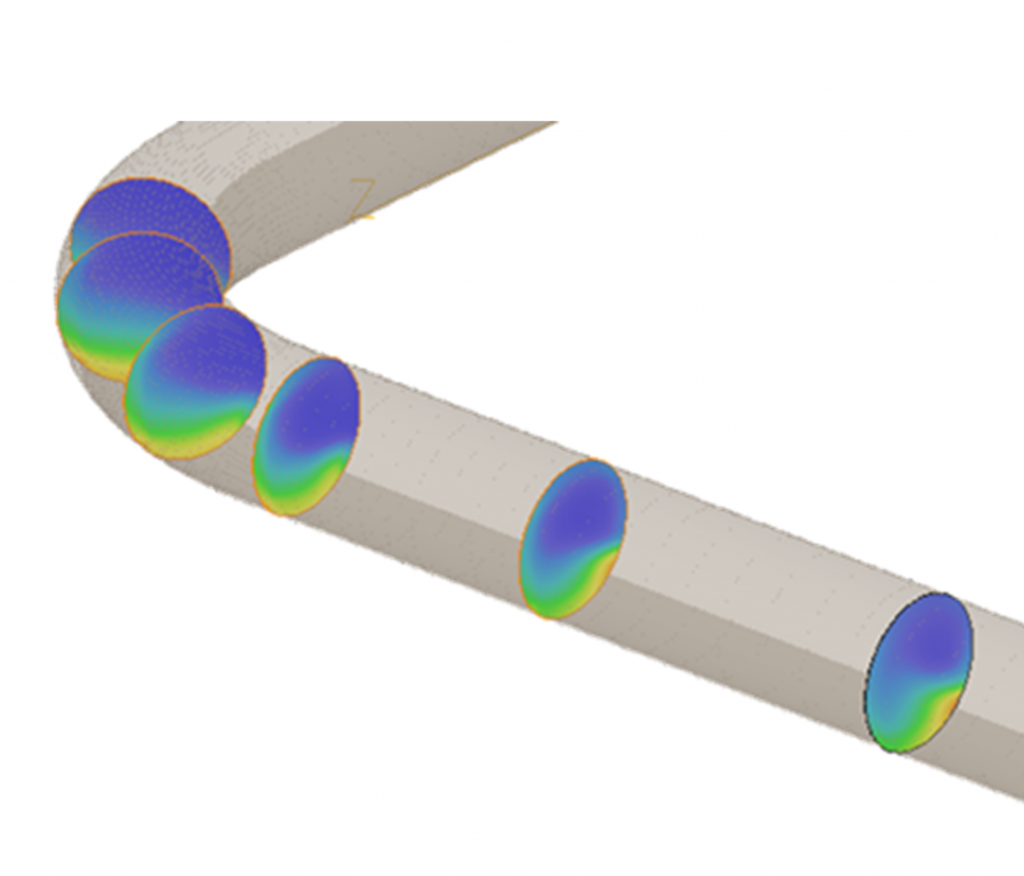

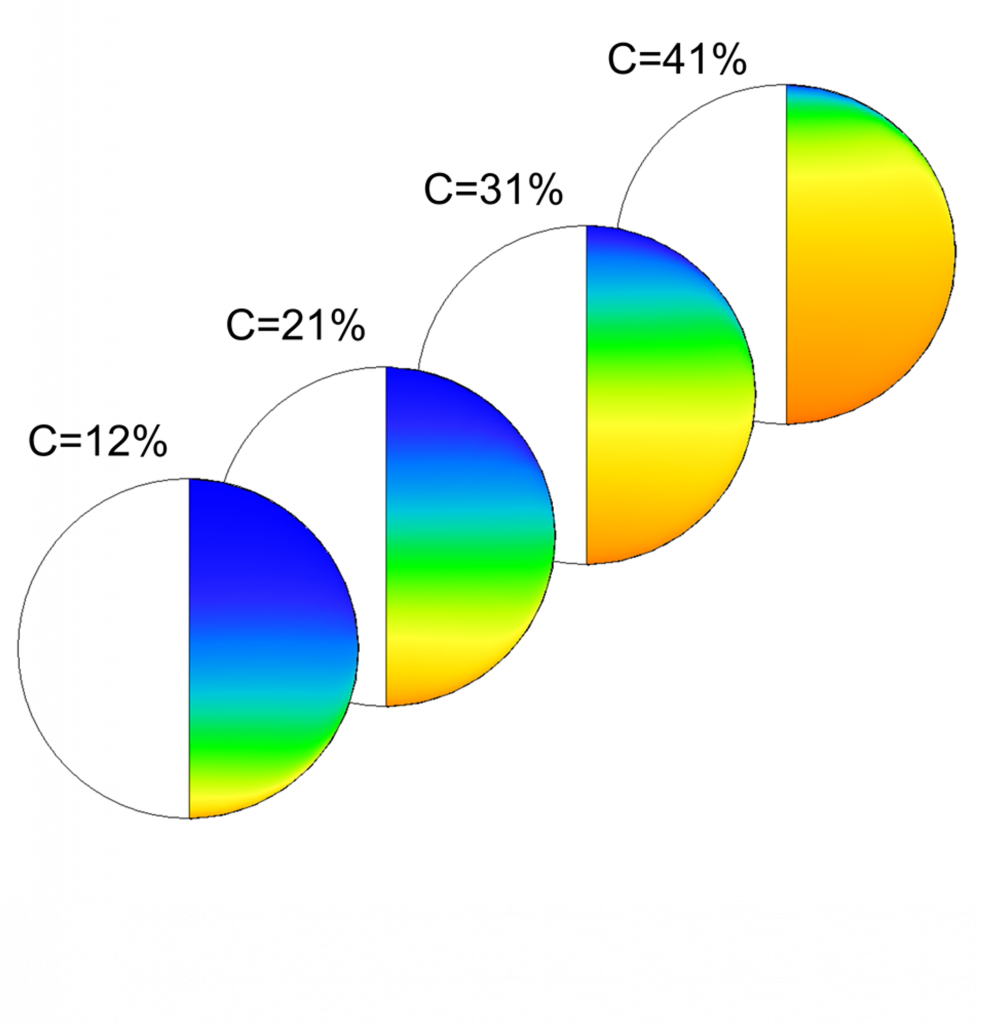

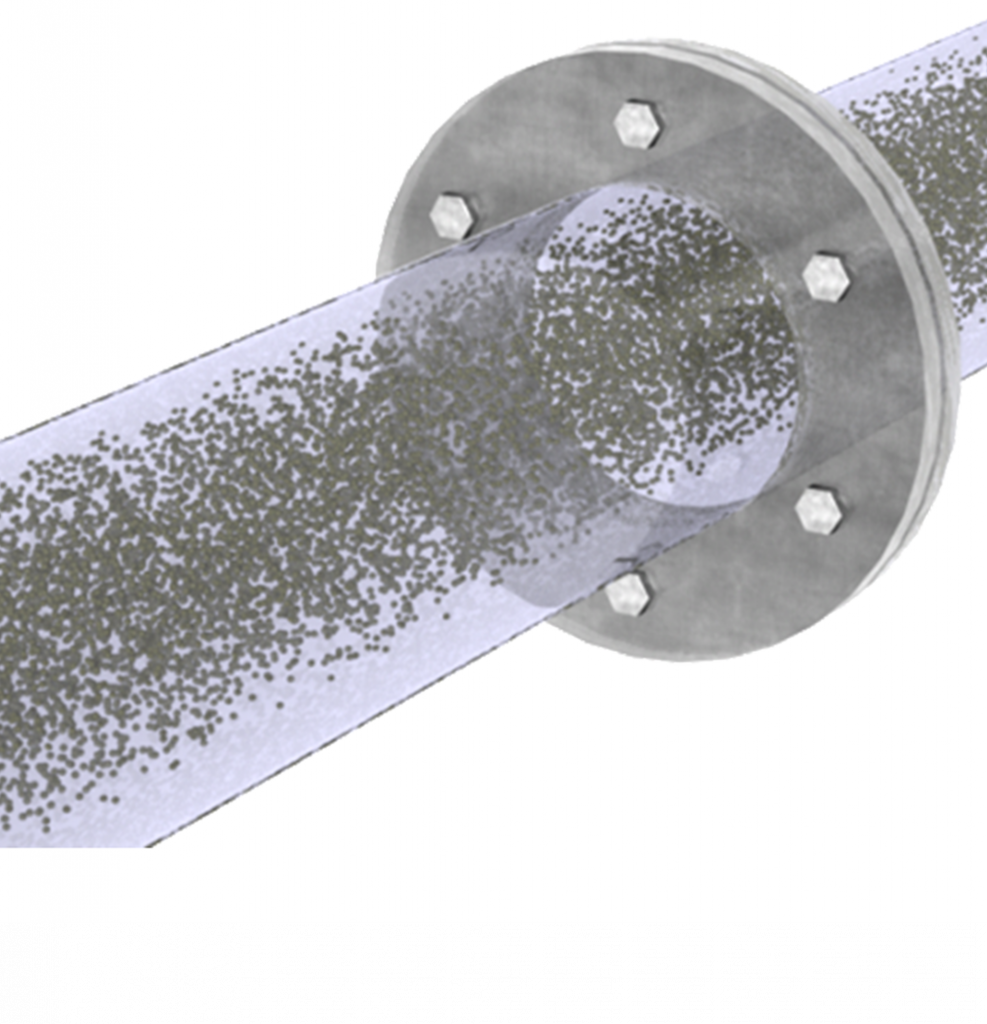

A slurry is a solid-liquid mixture with very high solid loading (up to 50%). These flows are frequently encountered in the mining industry, where slurry pipelines are used to transport the mineral concentrate to a mining processing plant near a mine. Other applications involving these flows are the CHOPS processes in the oil&gas industry and the fluidized beds in the chemical industry.

The modeling of slurry flows is particularly complex as it must account properly for the interactions between the fluid and the particles, between the particles and the solid walls, and among the particles themselves. The FLUIDLab group developed a two-fluid model for the simulation of slurry flows which, by comparison to experimental data reported in the literature, proved capable in efficiently predicting the features of most engineering interest. The research involved also CHAM Limited, and the two-fluid model was implemented in the PHOENICS code. A preliminary release of one of the developed models was implemented within a standalone application named Slurry SimScene.